Our Manufacturing Process

Each insole goes through a meticulous manufacturing process, where we combine precision technology with artisanal finishing. From footprint scanning to final assembly, every step is designed to deliver a personalized, functional, and durable solution for each of your patients.

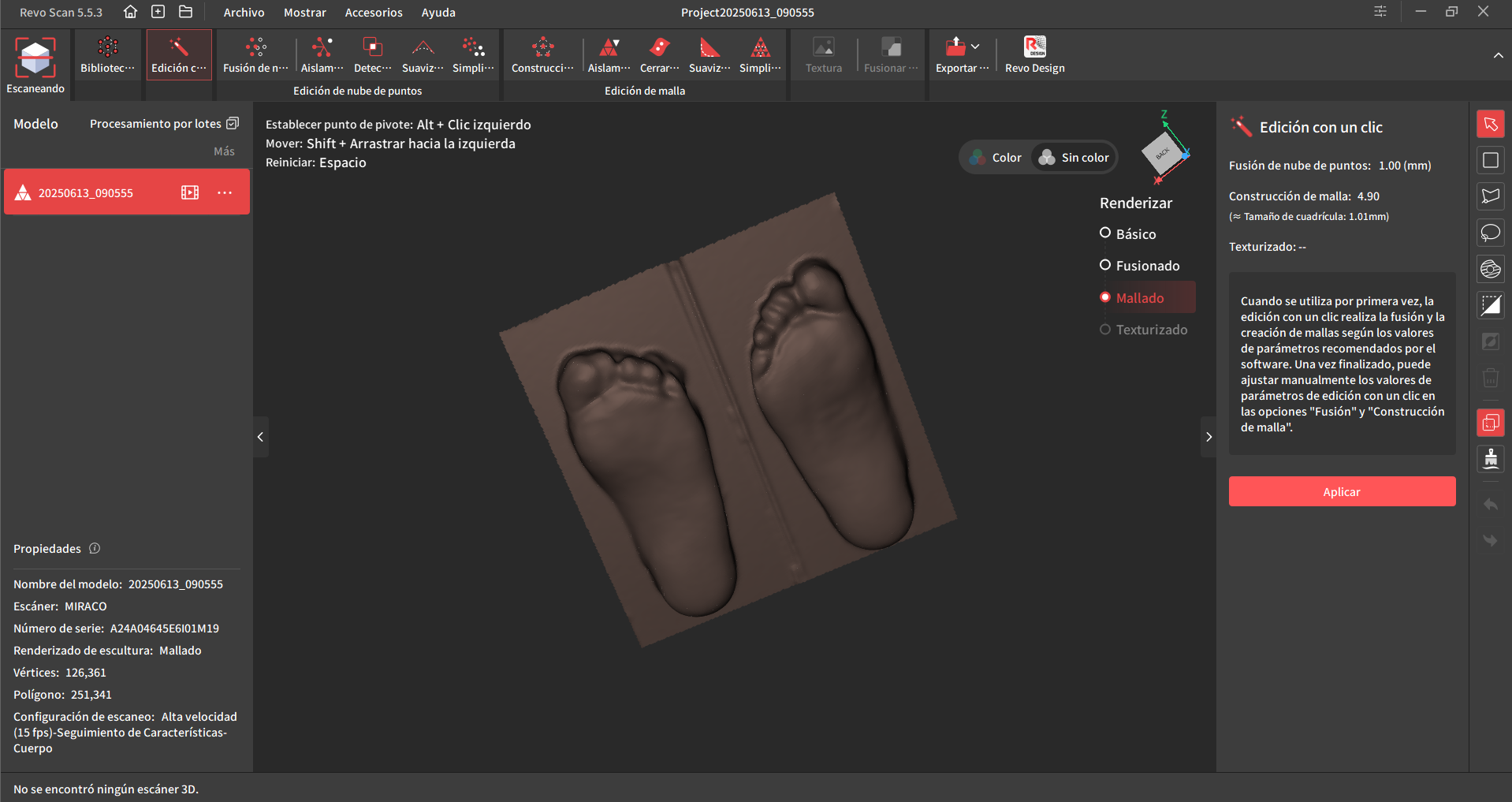

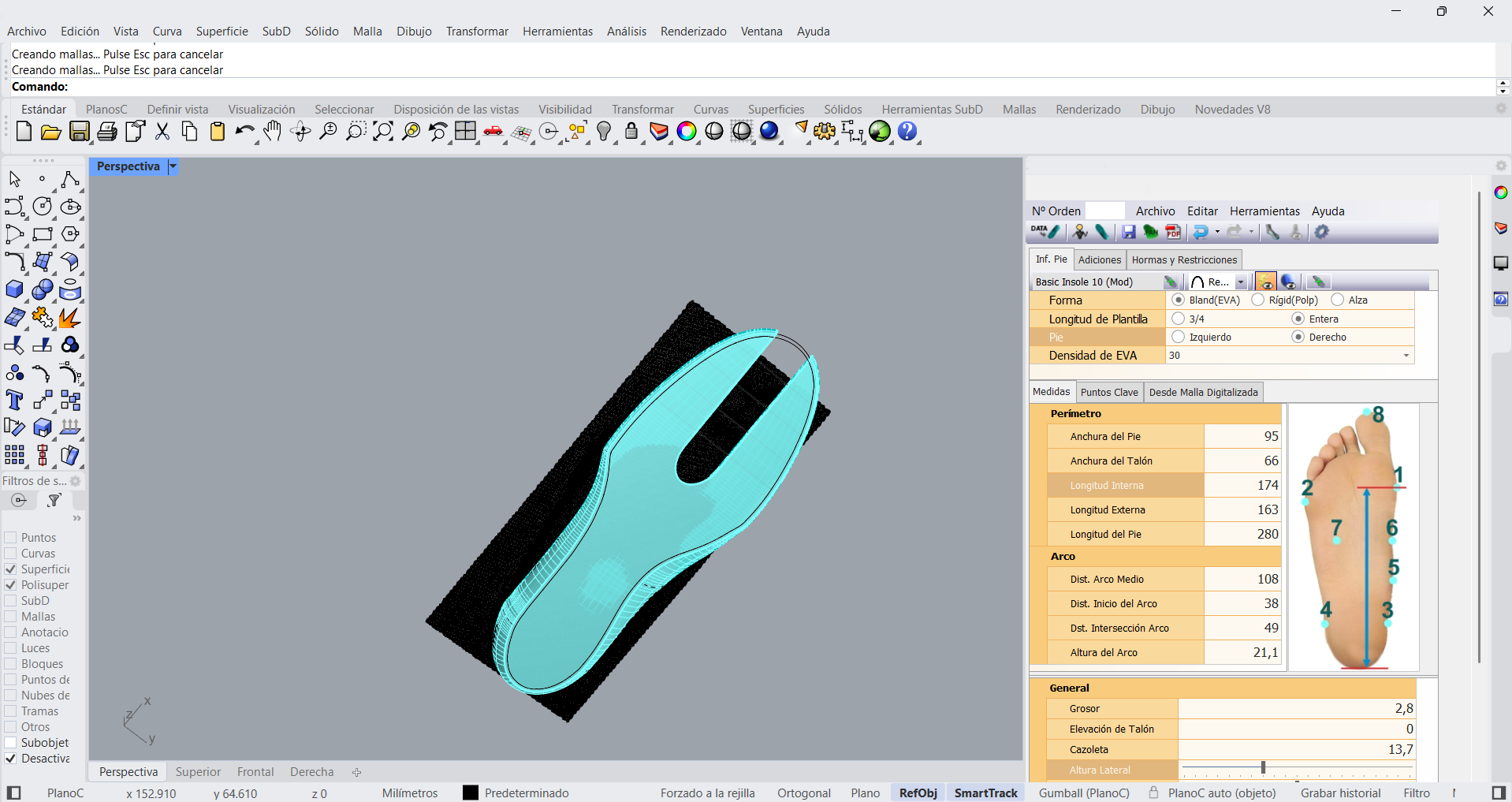

3D Design

The process begins with a 3D scan of the plantar footprint. Based on this digital model, we make the necessary modifications to adapt each insole to the podiatrist’s prescription and the patient’s specific morphology.

CNC

Once the design is validated, we move to manufacturing using high-precision CNC machinery. We offer a range of materials with different hardness levels, adapting to the biomechanical requirements of each case.

Sanding

After milling, the shells are manually sanded to remove imperfections, smooth edges, and optimize patient comfort without compromising orthotic functionality.

Assembly and Gluing

At this stage, linings and extrinsic additions are applied, always following the specifications provided by the professional.

Die-Cutting

Finally, the insole is die-cut to match the shape of the foot and the shoe. It is then reviewed and refined to ensure it is ready for use upon delivery.

Start Your Order Today

Don’t wait to offer your patients custom insoles of the highest quality. Sign up on StepLab, upload your scan, and let us take care of the rest.